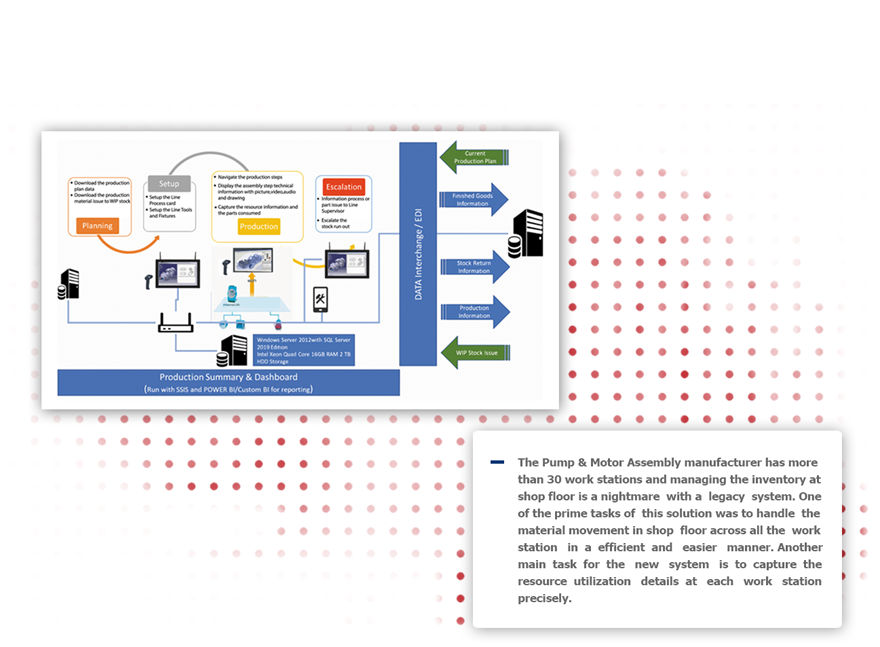

A Leading Motor Pump Manufacturer from south India wanted to automate their shop floor activities to have a precise control on materials and manpower handled at the production floor. This system was built using some IoT technologies that could help to monitor the work in real time and thus increase their Production capabilities.

A Leading Motor Pump Manufacturer from south India wanted to automate their shop floor activities to have a precise control on materials and manpower handled at the production floor. This system was built using some IoT technologies that could help to monitor the work in real time and thus increase their Production capabilities.

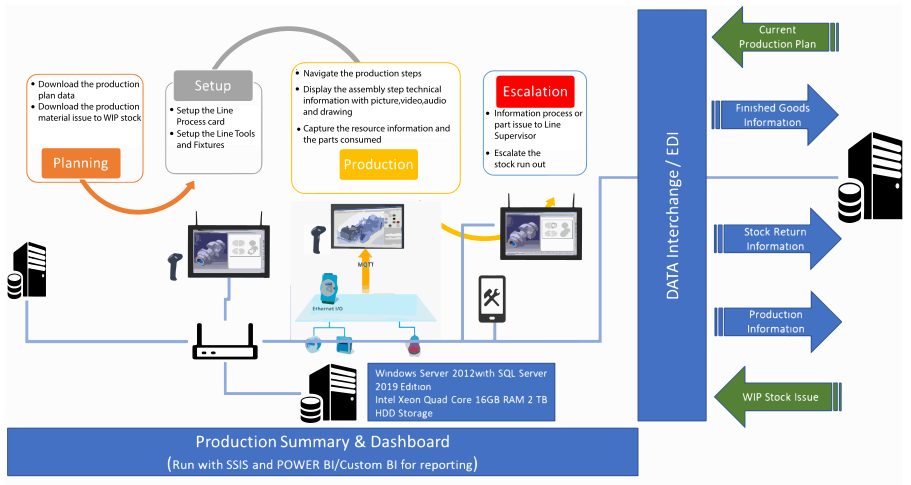

Customer required an IOT Based Production Line Automation for motor and pump assembly using Industry 4.0 standards that would have the work setup, managing the production and escalation of production faults and issues combined with a comprehensive production reports.

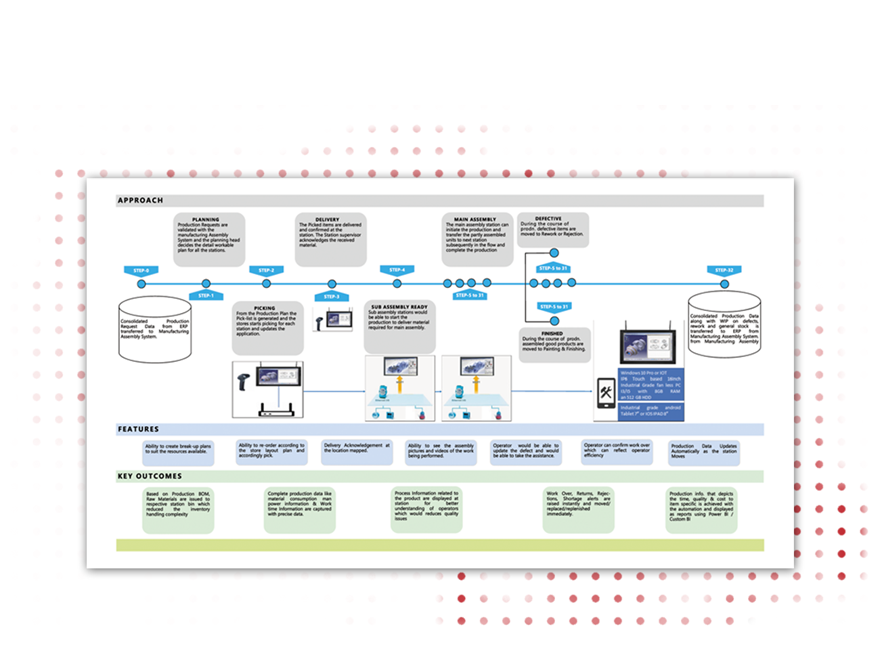

We developed an ioT based solution for capturing data from work station using Digital output IoT Wireless I/O Module at each work station and used QR Code scanner at the stations for confirming the materials correctness. The data captured are consolidated and shared to their centralized server for reporting and quick action purpose. The material picking would be done with a specially customized device which also helps to re-order/re-arrange items in pick list according to the store lay out plan and do the picking.

Here are some operational screens from the application.

For any of your software development, training and career needs please get in touch with us: